Replacing the hydraulics actuators with all electric servo actuators in older steam turbines.

Challenge

There are hundreds of steam turbines installed throughout the military and process industry that incorporate pre-1970 design. The valves on these turbines are predominantly operated by hydraulic actuators. Maintaining these hydraulic systems is costly with spare parts becoming more and more difficult to find. The control on these turbines in many cases is no longer adequate in today’s marketplace. Many plants that have older steam turbines are now upgrading them with digital controls and replacing the hydraulic actuators with all electric servo actuators from Exlar.

There are hundreds of steam turbines installed throughout the military and process industry that incorporate pre-1970 design. The valves on these turbines are predominantly operated by hydraulic actuators. Maintaining these hydraulic systems is costly with spare parts becoming more and more difficult to find. The control on these turbines in many cases is no longer adequate in today’s marketplace. Many plants that have older steam turbines are now upgrading them with digital controls and replacing the hydraulic actuators with all electric servo actuators from Exlar.

Application Solutions

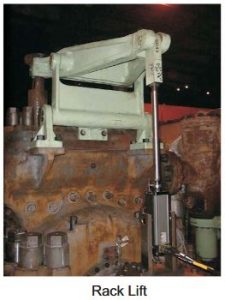

Steam Control Valve Steam turbines incorporate two basic arrangements of control valves: Shell Mounted and Chest Mounted. Shell mounted control valves are attached to the turbine shell. Some are modulated by a rack and cam arrangement. This valve operating method utilizes a common hydraulic cylinder to lift a rack of four to nine poppet valves in sequence. A fulcrum lever is used to multiply actuator force. Exlar directly replaces this main hydraulic actuator with a high performance servo electric actuator and positioner.

Benefit

Each Exlar actuator, when supplied with Exlar’s all-digital positioner, will respond to command signal changes in less than 5 mSec. The speed of the response combined with the dynamic capability of the all-electric actuator delivers repeatability much greater than typical pneumatic or hydraulic cylinders and allows for end-to-end travel time of a typical 6 inch stroke actuator of less than 200 mSec. This performance makes Exlar’s actuators the obvious choice for applications such as turbine controls.

Tri-Phase Automation is a distributor of Exlar in Wisconsin.

Contact Tri-Phase Sales or Get A Quote