Reflective light barriers and proximity switches used in sorting

A solution story from Pepperl+Fuchs

LEKO-Verpackungstechnik GmbH in Murnau designs and builds special machinery for confectionery technology. These special machines are designed for the isolation, packaging and boxing of small chocolate bars and pieces. The task of this system is to combine individual chocolate pieces into layers and then insert them into various vending boxes. During implementation two chocolate varieties (Napolitanis and alcohol-filled chocolates) and several vending box formats must be taken into account.

Implementation

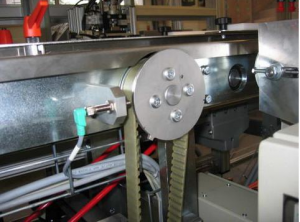

Via five sorting pots the chocolates are moved into the correct position and deposited in the correct orientation onto a collection conveyor. The jamming control of the sorting pots is controlled by reflective light barriers. The 180° rotation and the counting are triggered via light sensors with background light elimination and a fixed sensor distance. The reference position of the servo-motor axes is determined via inductive proximity switches.

The detection of packaged chocolates on the white conveyor belt is carried out by the reflection light sensor with background elimination ML4.1-8-H-20-RT. Due to its low black/white difference, the sensor reliably detects every passing item in spite of highly reflective aluminum packaging at a very small distance from the white conveyor belts. The fixed sensor distance prevents a maladjustment during ongoing production.

For the detection of products in the collector rail of the sorting pots, the stacking height of the lining placement unit and the jamming control of the vending boxes, the reflective light barrier with pole filter ML7-55/59/103 is used. The advantages of this light barrier for the client lie in its compact design and small visible beam spot. The distance between the reflective light barrier and the reflector can be kept extremely low.

The reference position of the servo axes is captured by the proximity switches.

Tri-Phase Automation is a distributor of Pepperl+Fuchs in Wisconsin.