SMAC has developed a unique solution for what is believed to be the fastest and most precise three axis pick and place system in the world today.

A solution was needed for a multi-national Japanese manufacturer of luxury goods who were required to both significantly increase product output and improve the flexibility of the manufacturing process.

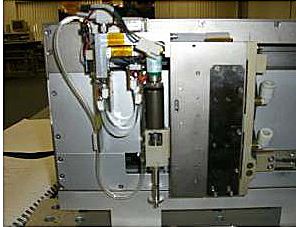

This highly innovative solution was custom designed by SMAC’s design engineering team in Carlsbad, California, USA. The customer was supplied with a completely pre-assembled, individual parts handling solution. It was designed to be quickly retrofitted into the existing production system within the customer’s factory. One of the key features of the SMAC Moving Coil Actuator solution is that by design it has inherent positioning and feedback capability, a closed loop system that ensures no external sensors or switches are required. This dramatically reduces the amount of external wiring required and facilitates both quick installation and 100% diagnostic feedback and data. The solution was rigorously tested in advance of delivery and ready to install as a turnkey unit. The pick and place system integrated two Multipole Moving Coil Actuators (MCA) one of which was a two axis rotary unit. The Y axis unit, part number MLA15-50 had a stroke of 50mm and the Z unit, part number MLRA15-30, has a stroke of 30mm and an in-built rotary axis of 180 degrees. Due to the exceptionally high speeds and high duty cycle air cooling was used to keep the temperature of the actuators constant. The electronic actuators achieve an exceptionally high degree of speed, accuracy and repeatability by the use of specially designed internal components and SMAC’s high performance electronics. C-sleeve linear guides deliver exceptionally high life expectancy, and a high resolution encoder is integrated into an optimized size footprint. The SMAC system is complemented by four high speed Galil electronic controllers which were incorporated into the solution.

This highly innovative solution was custom designed by SMAC’s design engineering team in Carlsbad, California, USA. The customer was supplied with a completely pre-assembled, individual parts handling solution. It was designed to be quickly retrofitted into the existing production system within the customer’s factory. One of the key features of the SMAC Moving Coil Actuator solution is that by design it has inherent positioning and feedback capability, a closed loop system that ensures no external sensors or switches are required. This dramatically reduces the amount of external wiring required and facilitates both quick installation and 100% diagnostic feedback and data. The solution was rigorously tested in advance of delivery and ready to install as a turnkey unit. The pick and place system integrated two Multipole Moving Coil Actuators (MCA) one of which was a two axis rotary unit. The Y axis unit, part number MLA15-50 had a stroke of 50mm and the Z unit, part number MLRA15-30, has a stroke of 30mm and an in-built rotary axis of 180 degrees. Due to the exceptionally high speeds and high duty cycle air cooling was used to keep the temperature of the actuators constant. The electronic actuators achieve an exceptionally high degree of speed, accuracy and repeatability by the use of specially designed internal components and SMAC’s high performance electronics. C-sleeve linear guides deliver exceptionally high life expectancy, and a high resolution encoder is integrated into an optimized size footprint. The SMAC system is complemented by four high speed Galil electronic controllers which were incorporated into the solution.

The new system enables perfect quality and allows production times to be tripled. It also enabled the customer to increase manufacturing throughput and flexibility by rapidly switching to new parts for different products quickly. Previously, manual machine change over of parts was required. The SMAC solution reduced existing cycle times from 900 milliseconds to 300 milliseconds while being operated 24/7. It is now believed that the SMAC solution sets a new benchmark as the fastest and most accurate pick and place machine automation system in the world. Because it is SMAC proprietary technology, it can be freely used for other customers and other applications. It is ideally suited for the handling of any micro-components where fracturing and damage occurs during the production process when using conventional solutions such as pneumatic devices, ball screw and servo systems. It is particularly suited to SMT and chip placing applications.

This application success story is from SMAC.

Tri-Phase Automation is a SMAC and Galil distributor in Wisconsin.

Contact Tri-Phase Sales or Get A Quote