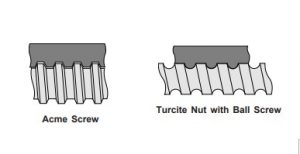

Lintech offers different types of sliding element nuts in linear table screw driven systems. The terms “lead” screw and “ACME” screw are talked about frequently. An ACME screw refers to a specific thread form which is trapezoidal in shape. A lead screw refers to screws which utilize nuts which do not have rolling elements. They are just sliding on the screw. An ACME screw is a type of lead screw. Lintech offers ACME style lead screws as well as lead screws which incorporate the shape of thread used for ball screws. Lintech will utilize Turcite, a polymer material shaped to mate to the ball screw form.

Utilizing a Turcite nut on a ball screw form produces a drive mechanism that has less friction than an acme screw, thus potentially allowing for higher speeds and less input torque required from an attached motor for a given application. It provides smooth motion, low audible noise, and is ideal for vertical applications. Also, using the Turcite nut with high lead ball screws provides for faster linear speeds.

So, a potential “downside” of an ACME screw is that it DOES have more friction than some other lead screws. However, that friction could also be a benefit of an ACME screw for some situations. For example, in a vertical orientation it may be the design of choice because in a situation where power is “lost”, that friction could possibly hold the load stationary vs. a “free fall” crash caused by gravity.

Tri-Phase Automation/IMAC is a distributor of Lintech products in Wisconsin and Illinois.