Electric motors are widely used in industries for industrial pumps, conveyors, compressed air systems, electric fans and more. Unfortunately, most of these motors either run at full speed or not at all. Since the speed cannot be altered on their own; these motors tend to use more electricity as a result. Industries can drive energy efficiency by using Variable Frequency Drives (VFD) in industrial and commercial applications.

Electric motors are widely used in industries for industrial pumps, conveyors, compressed air systems, electric fans and more. Unfortunately, most of these motors either run at full speed or not at all. Since the speed cannot be altered on their own; these motors tend to use more electricity as a result. Industries can drive energy efficiency by using Variable Frequency Drives (VFD) in industrial and commercial applications.

Tremendous Energy and Cost-Saving Potential

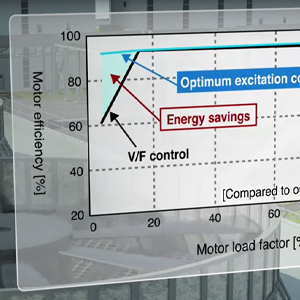

VFDs can reduce needless power consumption in many industrial and commercial applications by varying the speed (or frequency) of motors. VFDs are being widely adopted across a variety of industries including water, wastewater, food & beverage, mining, and oil & gas.

Essentially any application that uses motors to drive fans and pumps can find considerable savings when energy efficient VFDs are used. This is especially the case with HVAC systems in commercial buildings. These systems account for more than 40% of total energy use in the U.S.

For industries looking to comply with government’s new energy-efficiency standards or establish an energy-efficient system to reduce operational costs. VFDs are a fantastic way to do it. They can gain energy efficiency using Variable Frequency Drives

The FR-E800 Variable Frequency Drives from Mitsubishi Electric are designed to save energy and minimize cost with the ability to auto-tune IM and PM motors. We are a distributor partner of Mitsubishi Electric in Wisconsin and Illinois. Contact us and let us help you drive energy efficiency with variable frequency drives.