RFID Technology

Radio Frequency Identification (RFID) allows identification of an object without visual contact between reader and object to be identified. RFID technology from SICK can address many manufacturing challenges including asset management, quality control, genealogy, production execution and security.

Tri-Phase Automation/IMAC Motion Control commits to understanding not only IoT-enabled asset tracking technologies, but also your business, your processes, the people who need to use it, and your ROI objectives.

We can help you replace your old tracking method or implement a new system.

End-to-End Traceability Ensures Product Safety and Authenticity

The visibility that RFID asset tracking systems provide do more than protect products. They also improve speed and accuracy as products and assets are moved. Real-time tracking allows tighter tolerances for redundancy of both inventory and assets. That increases opportunities for eliminating waste and improving sustainability.

Continuous Identification with one Technology

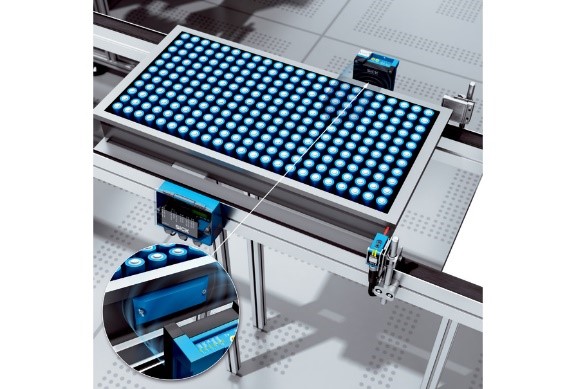

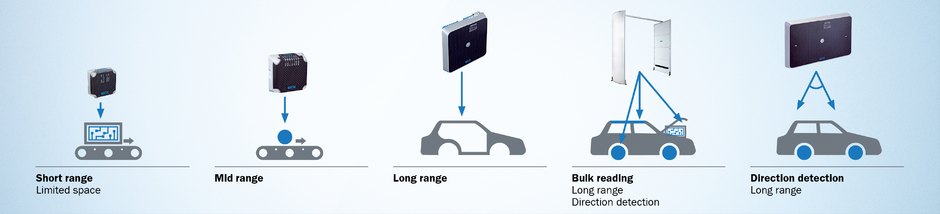

A single technology is possible for company-wide and continuous identification. From assembly of components to the shipment of the end product, SICK’s full line of RFID read/write units achieves complete transparency in production processes as well as logistics. Previously, this required the use of several technologies: LF and HF RFID solutions for the short range as well as UHF solutions for mid-range and long ranges. SICK now offers consistent and cross-company identification solutions with the UHF product family.

RFID technology is the foundation for this: IIoT applications with scanning ranges of 0 to 10 m, bulk reading and resistance to interfering factors such as dirt, light, and dust. Plus, a direct line of sight to the data card is also not required.

Intelligent UHF RFID identification

The RFU61X small read/write device is perfectly suited for IoT applications directly on the workpiece or component.

Intelligent RFID communication

The RFH6XX RFID read/write device for read ranges of up to 240mm. As a result of its compact design and integrated antenna, it can be used to flexibly and inexpensively expand existing systems.

The core of any RFID application or system is the software that powers it, and with customized software, the possibilities are endless!

We partner with AutomaTech who will customize your RFID data collection applications for real-time monitoring and analytical reporting.

Benefit from RFID Technologies

RFID can address many manufacturing challenges, including security, quality control, production execution, genealogy, asset management and more. A few of the benefits of RFID:

- Enhanced Quality and Traceability – RFID systems can help ensure that items have passed through all the correct checks and processes. RFID tagging can help ensure traceability by tracking an item right from its point of origin.

- Better Production Control – RFID can identify individual items or components: for example, to ensure that specific molds are filled with the correct volume of liquids and fired for the correct period of time, this helps reduce waste and improve efficiency.

- Saving Time and Money Through Automation – RFID applications can automatically track the movement of goods and upload the information to the ERP or financial management system. Removing the need for manual form filling and replace outdated spreadsheets.

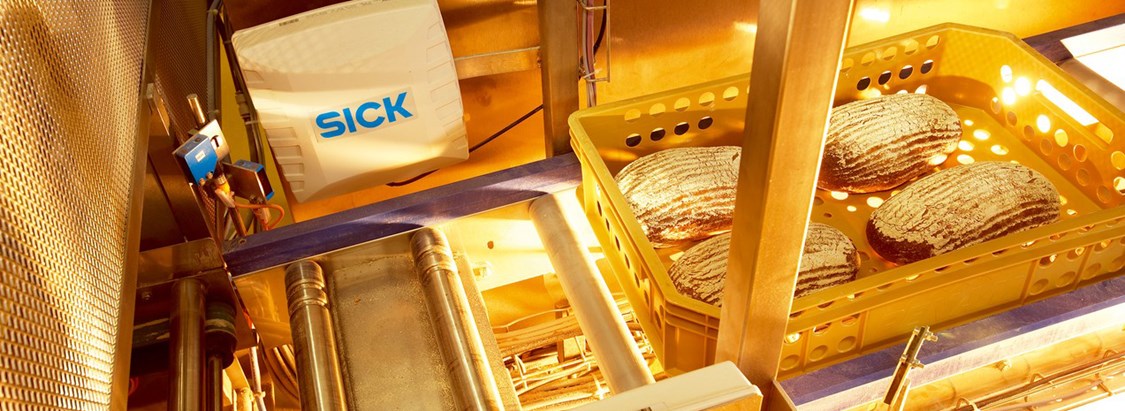

Remote data storage based on RFID technology is excellent for production control. Watch the Video

RFID Solutions

Fields of Applications:

- Workpiece identification on assembly lines

- Identification of production material in machines

- Load identification on mobile platforms

- Material procurement in E-Kanban

- Container identification in conveyor system

Assembly identification in the production process

RFID in the pharmaceutical industry