A Mitsubishi Electric and Bastian Solutions Success Story

Mitsubishi Electric products used in a stacker crane in an automated storage and retrieval system

When a customer asked Bastian Solutions, a Toyota Advanced Logistics company, to engineer a stacker crane for a new automated warehouse, they understood the magnitude of the challenge.

When a customer asked Bastian Solutions, a Toyota Advanced Logistics company, to engineer a stacker crane for a new automated warehouse, they understood the magnitude of the challenge.

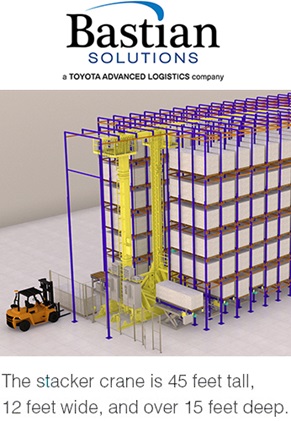

The automated stacker crane is a central component of the new automated storage and retrieval system (AS/RS). It transports packages of fiber cement boards from an immense racking system to workers at ground level. Over 12 feet long and weigh 12,000 pounds per package, the load is very heavy. Bastian Solutions knew a standard crane just would measure up it since typical crane loads are 2,000 to 3,000 pounds. Key considers included:

- The racking system for the AS/RS had to be built around the crane.

- The crane couldn’t be attached to the top of the building, because it could potentially take down the entire building.

- Multiple points of redundancy needed to be accommodated to meet safety.

It’s Like Lifting Five Toyota Sequoia SUVs

The Material Handling system integrator selected Mitsubishi Electric for the drive components. A specialized automated warehouse drive was just being introduced to the U.S. market and Allied Automation, a Mitsubishi Electric distributor in the area, was happy to provide it. They also brought in a third-party provider, SICK Sensor Intelligence, for the crane’s dual-laser distance sensor. That meant the drive had to interface with the laser feedback device.

The crane would be lifting the equivalent of five Toyota Sequoias throughout the day. The size, shape and weight of the load necessitated two vertical axes and two horizontal axes. Bastian Solutions’ project manager Tom Palcheck says, “We had to have multiple drives per axis working in coordinated motion to make it work.” And while some crane functionality was already engineered into the drive, there was a fair amount of custom firmware required.

- Droop control to accommodate the dual pulleys on the crane assembly for the large payload

- Horizontal sway control to make sure the load stayed level

- Dual-laser position control of the vertical axis to provide precise positioning measurement in a matter of milliseconds.

A Stand Alone Crane

Typically, the crane would be controlled by the Warehouse Control System (WCS). In this case, the crane was designed as a standalone system. All the intelligence is built into the drive to ensure a true representation of where the crane is at any given time. The drive communicates to the main PLC over a CC-Link IE Field Safety Network. This was a key part of the design, because there are two sources of feedback for the crane. Both the laser and the motor had to be taken into consideration. Therefore, it made sense to do it in the drive because it simplified the design.

Throughout the Factory Acceptance Test, the stacker crane met performance criteria with flying colors, achieving full-speed and full load results. This was the largest crane ever built by Bastian Solutions and their customer now has an automated crane that:

- Keeps track of where products are stored

- Shares information with an external system

- Handles heavy loads, but retains the accuracy, safety, performance and functionality expected of smaller cranes.

The automation solution includes Mitsubishi Electric Automation Products:

- MELSEC IQ-R Series Programmable Controllers

- CC-Link IE Filed Network

- FR-A-800 Plus Inverter (VFD/Variable Frequency Drive)

- CC-link Digital I/O Modules

This is a summary of the case study from Mitsubishi Electric, Allied Automation and Bastian Solutions.

Read the full story: Case Study – Bastian Solutions